Custom Precision Silicon Carbide Heat Exchanger

Custom Precision Silicon Carbide Heat Exchanger

| Unit Price: | 12999 USD |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

| Packaging: | Wooden pallets/ Cartons/Plastic stretch-wrap |

|---|---|

| Brand: | Zhang |

| Transportation: | Ocean |

| Place of Origin: | Jiangsu Wuxi |

| Supply Ability: | 150/Year |

| Certificate: | CE |

| Port: | Shanghai |

Product Description

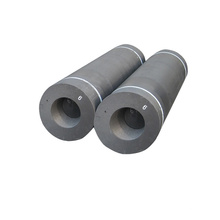

Characteristics of SiC heat exchanger

➤ Excellent thermal conductivity.

➤ Widely corrosion resistance ability.

➤ Abrasion and erosion resistance, medium can with high speed.

➤ Good mechanical properties.

➤ No risk of contamination to medium.

Our advantages for SiC Heat exchanger

1. Patent technology.

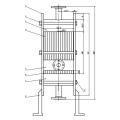

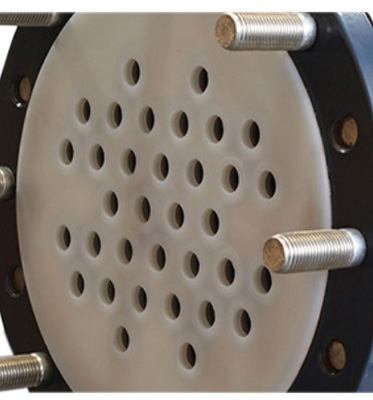

2. multiple choice for tubesheet,sigle tubesheet&multi-tubesheets,sigle tubesheet for commen condition, multi-tubesheets(Patent)significantly improves tube-plate rigidity, and greatly reduces the risk of leakage when under high temperature and high pressure.

3.With solution of vibration and fracture to SiC tubes.

4.Special design greatly reduces possible leakage points.

5. Active leak prevention technology. the heat exchanger can still run normally even slight leakage happens to the gasket.

2. multiple choice for tubesheet,sigle tubesheet&multi-tubesheets,sigle tubesheet for commen condition, multi-tubesheets(Patent)significantly improves tube-plate rigidity, and greatly reduces the risk of leakage when under high temperature and high pressure.

3.With solution of vibration and fracture to SiC tubes.

4.Special design greatly reduces possible leakage points.

5. Active leak prevention technology. the heat exchanger can still run normally even slight leakage happens to the gasket.

6.Can be an independently heat exchanger , also can be used as internal parts.

7.Experienced heat transfer calculation ability and research team.

8.Strong technical team of anticorrosive equipment.

9. Quick response after sales service.

Excellent thermal conductivity of SiC

Corrosion resistance of SiC

| corrosive medium | temperature (℃) | corrosion rate (mg/cm2.Y) | corrosion rate (mm/Y) |

| 98% H2SO4 | 100 | 0.98 | 0.0032 |

| 54% HF | 25 | 0.06 | 0.0002 |

| 50%NaOH | 100 | 1.25 | 0.0040 |

| 45%KOH | 100 | 0.04 | 0.0001 |

| 70%HNO3 | 86 | 0.04 | 0.0001 |

| 37%HCl | 25 | 0.07 | 0.0002 |

| 10%HF+HNO3 | 25 | 0.05 | 0.0002 |

| 10%HF+HNO3 | 120 | 1.25 | 0.0040 |

Main application of SiC heat exchanger

Shortcomings of other heat exchangers

Shortcomings for graphite heat exchanger

Shortcomings for glass-lined heat exchanger

Shortage of fluoroplastic heat exchanger

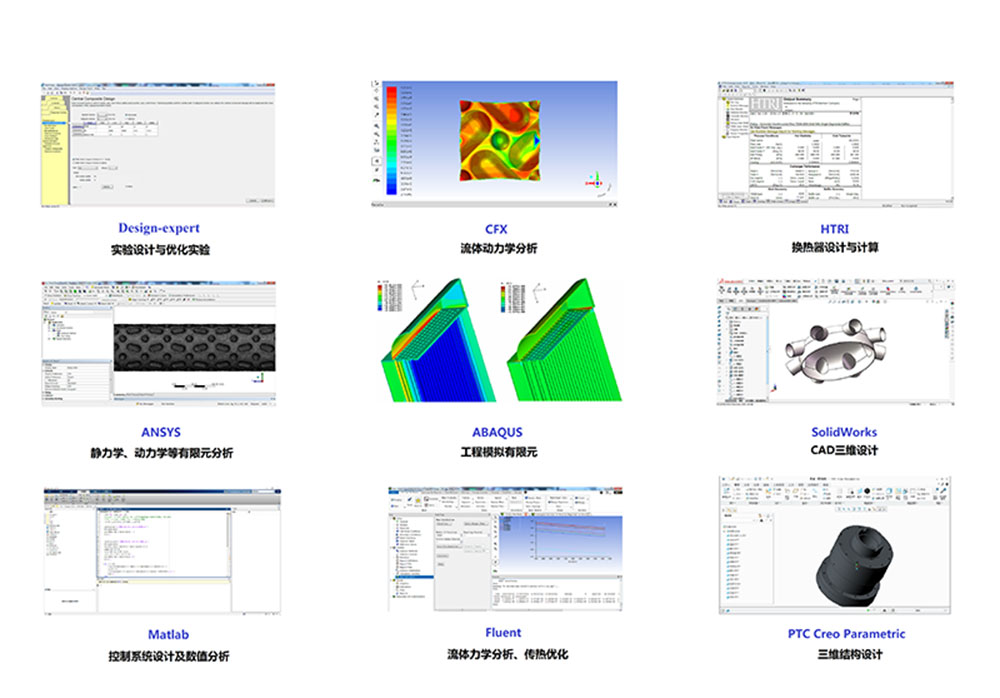

Design / Calculation Software

Custom Service

➤Our Products for pharmaceutical and chemical industries

1. Multifunctional “Three in One” (filtering, washing and drying)

1. Multifunctional “Three in One” (filtering, washing and drying)

2. Crystallizing Tank, Reaction Kettle

3. Sterile double-cone dryer

4. Rake Vacuum Dryer

5. Plate-fin Heat Exchanger

➤Our advantage

Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel, etc.

Ti/HC22/Mone11

Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel, etc.

Ti/HC22/Mone11

2. Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3. Design/Calculation Software

➤scope of business

1. On-site Inspection

➤scope of business

1. On-site Inspection

2. Technical Innovation Plan for Equipment Technical Improvement Plan for Equipment’s Structure Optimization Fast and Effective Solution to Equipment Malfunctions Highly Efficient and Precise On-site Construction Service Commitment to a Deadline in Customization A Full Range of long-term on-site technical maintenance service

3. Maintenance

4. Technical Solutions

5.On-site Testing and Training

6. Spare Parts

Company Profile

Product Categories : Crystallizer > Heat Exchanger

Hot Products

Black silicon carbidesilicon metal 1101low sulfur low ash pitch cokefoundry coke/ met coke /metallurgical coke productsLow Sulfur Metallurgical Coke Pricealloy furnace use graphite electrode paste/carbon electrode pasterecarburiser, carbon additive, carbon risercalcined anthrciate coal /carbon additive priceLow Sulphur Graphitized Petroleum Coke For Steel Makinggraphite powdergraphite powdergraphite powder for salesblack silicon carbidePETROLEUM COKEfuel grade petroleum cokes from usahot sales calcined petroleum coke / cpc