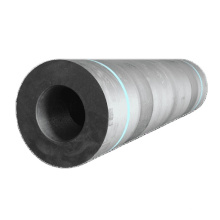

High Quality UHP Graphite Electrode Price

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1000 Ton |

| Delivery Time: | 180 Days |

| Packaging: | Wooden box and tray packaging, should be fixed by steel belt |

|---|---|

| Productivity: | 100,000 tons |

| Brand: | Tengfei carbon |

| Transportation: | Ocean,Land |

| Place of Origin: | Taigu County, Shanxi Province |

| Supply Ability: | 50,000 tons |

| Certificate: | GB/T19001 GB/24001 GB/28001 |

| Port: | Tianjin Harbor |

Basic Info

Model No.: 550mm*2700mm

Product Description

It is divided into conventional power, high power, ultra high power and ultra high power.

High quality ultra high pressure Graphite Electrode price

Artificial graphite electrodes are made of high quality low ash materials such as Petroleum Coke, needle Coke

And coal tar pitch, calcined, compression molded, kneaded, formed, baked and pressure impregnated, graphitized

It is then precision machined by professional CNC machining. The product has

It has the characteristics of low resistivity, good electrical conductivity, low ash content, compact structure, good oxidation resistance and high mechanical strength. It is the best conductive material for electric arc furnace and smelting furnace.

Precautions for using graphite electrodes

1. The electrode holder should be fixed outside the safety line of the top electrode. Otherwise, the electrode is easy to break. The contact surface between the bracket and the electrode should be cleaned regularly. In order to maintain good contact, the cooling jacket of the bracket should be avoided.

2. Determine the cause of the gap in the electrode junction and do not use them until the gap is removed.

3. When connecting the electrodes, if the nipple bolts fall off, the nipple bolts need to be installed.

4. The use of the electrode should avoid tilting operation, especially the group of connected electrodes should not be placed horizontally to avoid cracking.

5. When loading the furnace, bulk material should be loaded to the bottom of the furnace to minimize the influence of the furnace charge on the electrode.

6, smelting should avoid the bulk of insulating material deposited on the bottom of the electrode, so as not to affect the use of the electrode or even crack.

7. When raising or lowering the electrode, do not collapse the cover, otherwise the electrode may be damaged.

8. It is necessary to prevent the steel slag from splashing onto the threads of the electrodes or nipples stored in the melting place, which may damage the accuracy of the threads.

| HP Graphite Electrode | ||

| Propertises | unit | Numerical value |

| Bulk density | g/cm3 | 1.65-1.70 |

| Specific resistance | μΩ·m | 6.5-7.5 |

| Ash content | % | 0.3-0.5 |

| Flexural strength | Mpa | 12-16 |

| Elastic modulus | Gpa | 12-16 |

| C.T.E | 10-6/°C | 2.4-2.2 |

| UHP Graphite Electrode | ||

| Propertises | unit | Numerical value |

| Bulk density | g/cm3 | 1.68-1.75 |

| Specific resistance | μΩ·m | 5.5-6.5 |

| Ash content | % | 0.3 |

| Flexural strength | Mpa | 16-20 |

| Elastic modulus | Gpa | 16-20 |

| Norminal Diameter | IEC Code | Sizes of Nipple | | Sizes of Socket | Thread | ||||

| mm | in | | D | L | d2 | l | d1 | H | mm |

| 200 | 8 | 122T4N | 122.24 | 177.80 | 80.00 | <7 | 115.92 | 94.90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4N | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 355.60 | 177.90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 304.80 | 158.80 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 457.20 | 226.58 | 292.13 | 234.60 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317.50 | 355.60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317.50 | 457.20 | 228.70 | <10 | 311.18 | 234.60 | 8.47 |

| 250 | 10 | 155T3N | 155.57 | 220.20 | 103.80 | 147.14 | 116.00 | ||

| 300 | 12 | 177T3N | 177.16 | 270.90 | 116.90 | 168.73 | 141.50 | ||

| 350 | 14 | 215T3N | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | ||

| 400 | 16 | 241T3N | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | ||

| 450 | 18 | 273T3N | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | ||

| 500 | 20 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

Product Categories : Ultra High Power Graphite Electrode